Leading the world in

energy absorption

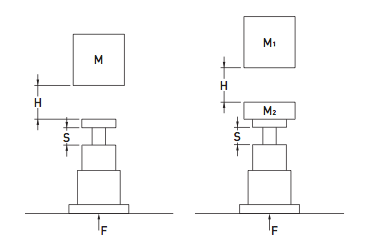

| Design mass for buffer | Ep = Mg(H+S) |

| Maximum impact force |

|

| Design mass for buffer |

or or

|

| Initial Plunger Velocity |

|

| Multiple Mass Case: | |

| Potential energy to be absorbed Maximum impact force | Ep = M1g (H+S) + M2gS |

| Maximum impact force |

|

| Initial Plunger Velocity |

|

| Buffer design Mass |

|

To avoid confusing conventions within calculations always use SI units in formulae then convert to more appropriate units if required.

| Notation | Quantity | SI Unit |

| M | Mass of body | kg |

| M | Mass of body | kg |

| M | Mass of body | kg |

| Me | Buffer design mass | kg |

| Me | Freefall height | m |

| S | Buffer stroke | m |

| Ep | Potential energy | J |

| v | Velocity | m/s |

| F | Maximum Impact force | N |

| m/s2 | Acceleration due to gravity | g |

| n | Number of buffers in parallel | - |

| ξ | Efficiency | - |

Eg. Consider a body of mass (M1) = 22000kg (22 tonnes) / free falling onto another body of mass (M2) 3000kg (3 tonnes) supported by a buffer.The free fall height (H) being 0.15m. A typical example of this being in catch gear buffers for mine cages where 4 Type 4-114mm stroke buffers are used; this is a multiple mass case.

To find the equivalent energy absorbed:

Ep = M1 g (H+S) + M2 g S = (22000).(0.15+0.114) x 9.81 + 3000 x 9.81 x 0.114 = 60331.5J = 60.3315kJ

To find the maximum impact end force:

F = 661529.6N = 661.5296 kN

To find the equivalent mass for metering pin selection:

Initial plunger velocity

By selecting a Type 4 buffer with a dynamic capacity of 1000 kN these requirements are met.Therefore select metering pin code 05 for masses up to 20000kg (20 tonnes).