Leading the world in

energy absorption

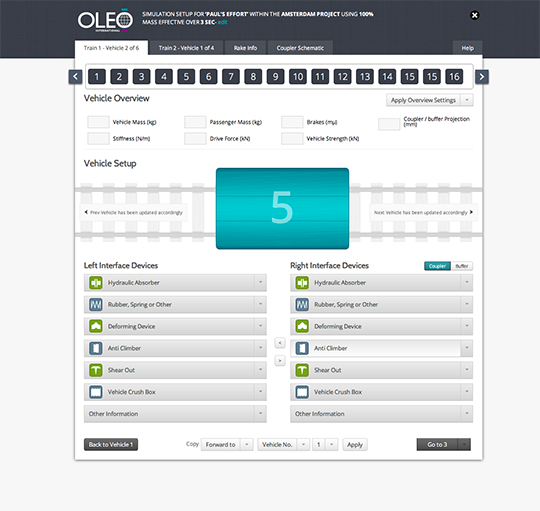

Oleo 1D is a one dimensional software program that accommodates the combined effects of couplers, buffers and anti climbers with approximate crush behaviours of vehicle ends.This is good for investigating the sensitivity of the whole train Crash Energy Management (CEM) system for collision response.The software is particularly useful in evaluating the options for various energy absorption methods used in bolt on devices including couplers, buffers, anti climbers and other crush elements.

The software inputs are flexible so that a specific train can be modelled and various collision scenarios simulated.

Each vehicle in the train is modelled as rigid bodies with a stiffness characteristic.

The hydraulic units are selected from a library of designs that can be customised and their specific dynamic behaviour verified by full size physical testing.

The characteristics of linear devices such as rubber, elastomer, deformation tubes, crush boxes and shear out mechanisms can be selected. Specific alternative characteristics can be entered.

The specific geometry accommodating the coupler, buffers and anti climbers can be reflected along with their characteristics for each vehicle in the rake.

The approximate crush behaviour of the ends can be entered as linear force vs. distance data from separate detailed finite element analysis.

Once the basic train and its energy management setup have been modelled then it is possible to run various collision scenarios including the following:

1. Train into terminal buffer stops with sliding or fixed buffer stop solutions

2. Train into train - either same configuration or a different train configuration altogether

a. Moving train into stationary train – with & without brakes

b. Moving trains at different speeds and directions