Leading the world in

energy absorption

We pride ourselves on being innovative in response to both customer demands and technological opportunities. Continuous investment in research and development, state of the art technology and modern manufacturing processes has made Oleo leading experts in energy absorption.

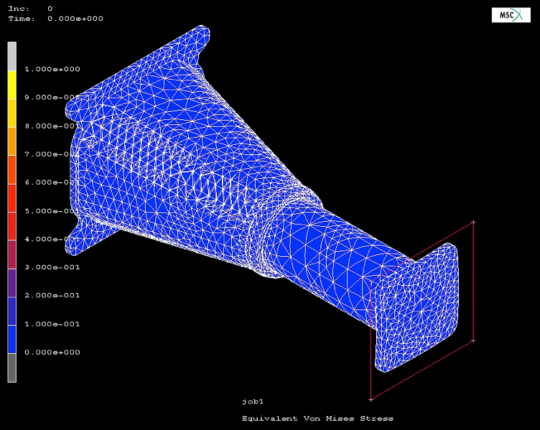

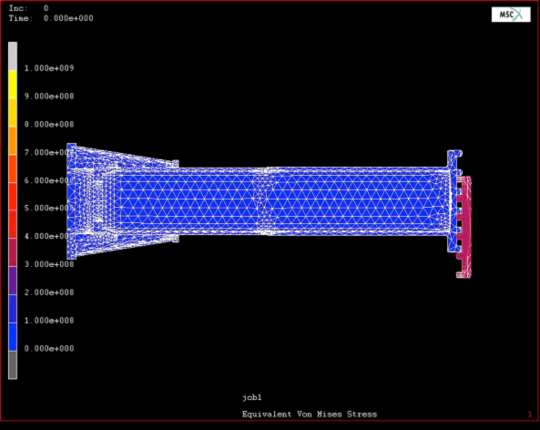

Using our in house simulation software and testing equipment it has been possible to develop new technologies. Research and development is ongoing at Oleo with new services being introduced and products patented.

Oleo has a complete range of elevator buffers for every application offering a high quality product with minimum life-cycle costs.

Fitting efficient and effective buffer stop solutions will protect passengers, rolling stock and infrastructure in the event of a train failing to stop.

Oleo's industrial energy absorption solutions offer products and services for dockside applications, steelworks, rail infrastructure, and other specialist bespoke applications.

Oleo provides crash energy management products and services to rail operators and train manufacturers. Over 1,000,000 Oleo hydraulic and deformation impact energy absorbers are in daily operation around the world; meeting the requirements for higher levels of protection for passenger and freight rolling stock and operating needs such as higher coupling speeds.