Leading the world in

energy absorption

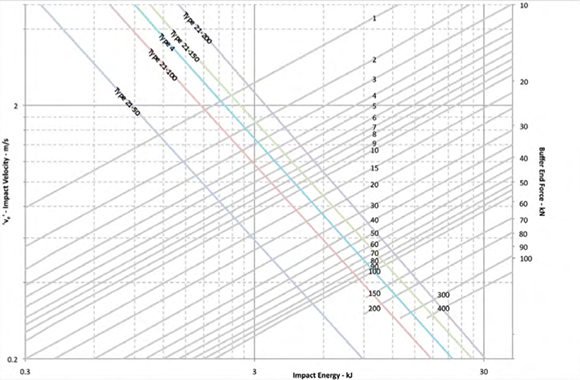

Before using the chart, it is necessary to know the impact Mass 'Me' and the impact velocity 've' of the moving machine. On very wide track machines such as travelling cranes, the mass on the rail can vary considerably due to asymmetric loading, or the position of the trolley. In these cases the maximum mass on the rail MUST BE used and each side of the bridge dealt with separately.

Impact into stops

Project a horizontal line from the 've' scale across the chart, to intersect with the inclined impact mass line 'Me'.Through this point make a vertical line to the bottom scale to obtain the impact energy to be absorbed per buffer. From the points at which this vertical line intersects the diagonal buffer lines, project horizontal lines to the right hand scale to obtain the force per buffer.

It may be found that an intersection between the velocity line and the impact mass line cannot be made on the chart. This indicates that the energy to be absorbed is above the capacity of a single buffer, and the above exercise should then be repeated for a case 2 impact. i.e. add an extra buffer, making sure that the impact Mass 'Me' and impact velocity 've' are correct.This formula is shown in Load Cases section.

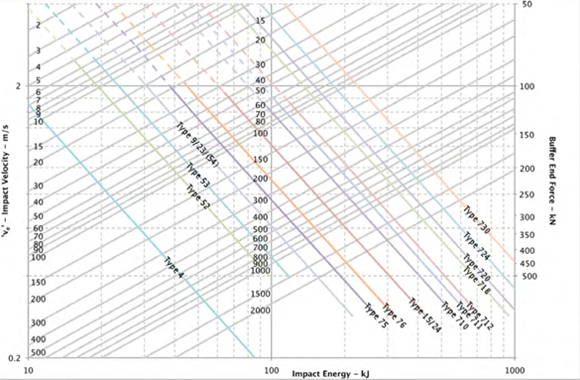

Impacts between two moving structures

The procedure is the same as outlined above, but again first make the corrections for impact Mass 'Me' and velocity 've' from the formula in the Load Cases section, which takes into account the Mass and velocity of both machines.

Commence with Case 3 and repeat for Case 4 if the buffer Energy capacity has been exceeded or if the Buffer resistance is too high, i.e. add an extra buffer.

Buffers in parallel

Impact conditions 1-4 cover a single buffer or two in series.To obtain additional energy absorption capacity these arrangements can be duplicated, so that forces are shared. When this is done the Impact Mass per buffer 'Me' given in the table must be halved.

Such an arrangement is sometimes advantageous when length is limited and forces on the buffer stops are not vital, so that Case 1 in duplicate can be used instead of Case 2.

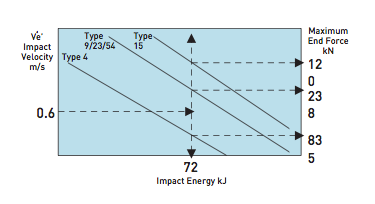

Buffers for a crane into an buffer stop Take case 1 Impact condition

Deal with the mass on the rail at each end of the bridge separately. Mass of the crane bridge ONLY at one end = 250000kg = 250 Tonnes

Additional mass from the trolley positioned at that end (0.75 of total span) = 150000kg = 150 Tonnes Me = 150000kg + 250000kg = 400 Tonnes

Maximum impact velocity, ve = 0.6m/s

Read from chart: Energy to be absorbed per buffer = 72kJ

Type 4 buffer force = 835kN

Type 9 buffer force = 238kN Type 15 buffer force = 120kN

An ideal choice would be for the Type 9 buffer

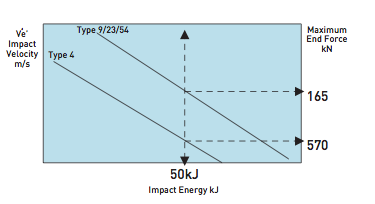

E.g. Buffer for body rolling into an buffer stop, with a requirement that the maximum impact energy does not exceed 50kJ. Use the nomogram to evaluate the end force.

Type 4 = 570kN

Type 9, 23, 54 =165kN

| Total crane weight | Trolley weight | Crane velocity |

| 700Tonnes | 200Tonnes | 0.6m/s |