Leading the world in

energy absorption

These devices are very efficient at absorbing energy by controlled deformation. However, by their nature these are 'single use' and are most commonly used with a recoverable energy absorber.

The combination of a deformation tube and recoverable energy absorption is a very effective way of enabling rolling stock to have good crash protection and low operating costs by avoiding repair costs arising from minor collisions and coupling activities.

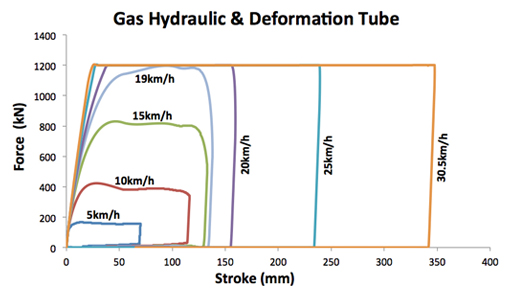

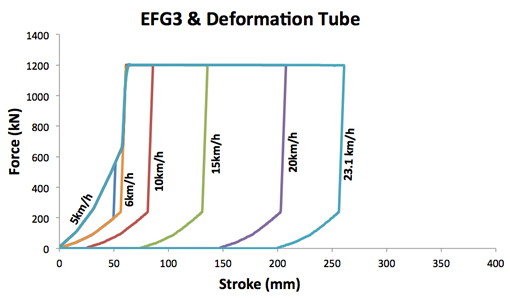

Gas hydraulic capsules are velocity sensitive and as speeds rise allow both devices to work together to utilise the full stroke, this maximises the energy absorption of their combined stroke. This very useful feature is illustrated by comparing the crash performance of two 50 tonne rail vehicles fitted with a 1200kN 200mm stroke deformation tube and either an EFG or an Oleo gas hydraulic unit.

The graph below shows the gas hydraulic and deformation tube:

GAS HYDRAULIC AND DEFORMATION TUBE

This combination allows fully recoverable gas hydraulic only energy absorption up to 19km/h and as collision speeds increase the Oleo gas hydraulic and deformation devices work together to more absorb energy across the combined stroke. This allows the structure of the rail vehicle to be protected at crash speeds up to 30km/h.

The graph below shows an EFG and a deformation tube:

EFG3 AND DEFORMATION TUBE

The EFG works first in isolation and absorbs very little energy over its stroke regardless of impact speed. Consequently the deformation tube starts to stroke at 6km/h but can protect the structure of the rail vehicle up to 23km/h.