Leading the world in

energy absorption

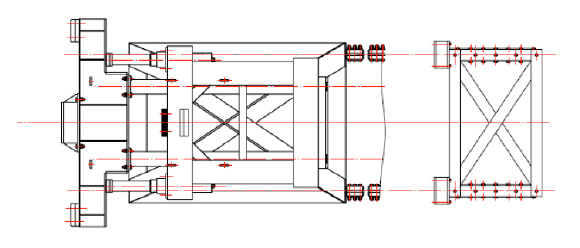

Contains one pair of anti-climber shoes, two Oleo Type 9 hydraulic buffers and one set of XCD fixed stop friction shoes.

Impacting point from the top of the rail (coupler height): mm (720 – 660 – 824)

Examples for conditions and installation length:

(1) 8 Cars

For cars with passengers. Train mass 510t, Impacting speed 25km/h, Installation length 25m, Impact capacity: 448kJ Recoverable Stroke: 400mm

For cars without passengers – testing line Train mass: 300t, Impacting speed: 25km/h, Installation length: 18m, Impact capacity: 448kJ Recoverable Stroke: 400mm

For cars with passengers. Train mass: 510t, Impacting speed: 15km/h, Installation length:15m, Impact capacity: 448kJ Recoverable Stroke: 400mm

(2) 6 Cars

For cars with passengers. Train mass: 380t, Impacting speed: 25km/h, Installation length: 15m, Impact capacity: 448kJ, Recoverable Stroke: 400mm.

For cars without passengers – testing line. Train mass: 220t, Impacting speed: 25km/h, Installation length: 15m, Impact capacity: 448kJ Recoverable Stroke: 400mm.

For cars with passengers. Train mass: 380t, Impacting speed: 15km/h, Installation length: 15m, Impact capacity: 448kJ Recoverable Stroke: 400mm.