Leading the world in

energy absorption

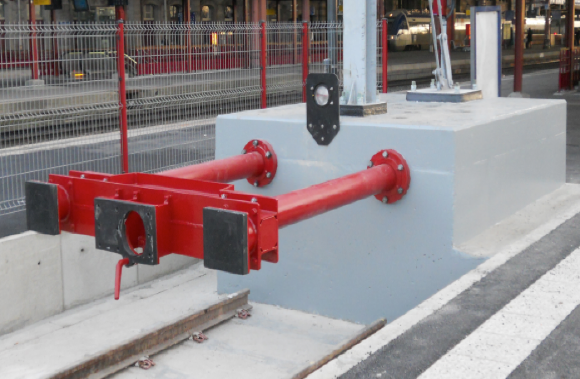

Oleo hydraulic energy absorption systems are used to dissipate the impact energy supported on a fixed concrete base foundation. These are generally used in conjunction with a 'buffing beam' or 'buffing trolley' to interface with rolling stock. These systems also have the ability to self-reset after impact.

Design advice can be provided in relation to the concrete base foundation.

Typically used on metro & main line - designed for centre and side impact. Concrete base foundation incorporating Oleo hydraulic units [two Oleo Type 718 - Recoverable stroke: 1800mm] Train mass: 267 tonnes, Impacting speed: 12km/h, Impact capacity: 2016kJ, Installation length: 5.5m

Typically used on metro & main lines - designed for centre and side impact. Concrete base foundation incorporating Oleo hydraulic units [two Oleo Type 724 - Recoverable stroke 2400mm] Train mass: 300 tonnes, Impacting speed: 14km/h, Installation length: 8 metres, Impact capacity 2688 kJ

Typically used on metro, main line and depots - designed for centre and side impact.

Concrete base foundation incorporating Oleo hydraulic units [three Oleo Type 712 - Recoverable stroke: 1200mm]

Train mass: 1000 tonnes, Impacting speed: 1.94m/s, Impact capacity 2016kJ, Installation length: 3.5m

Typically used on metro & main lines - designed for centre and side impact. Concrete base foundation incorporating Oleo hydraulic units [two Oleo Type 730 - Recoverable stroke 3000mm] Train mass: 510 tonnes, Impacting speed: 12km/h, Installation length: 9.5 metres, Impact capacity 3360 kJ