Leading the world in

energy absorption

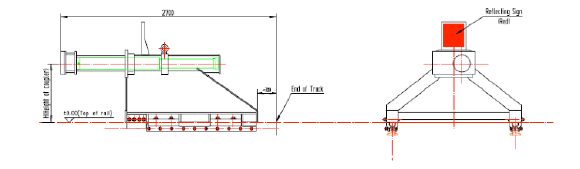

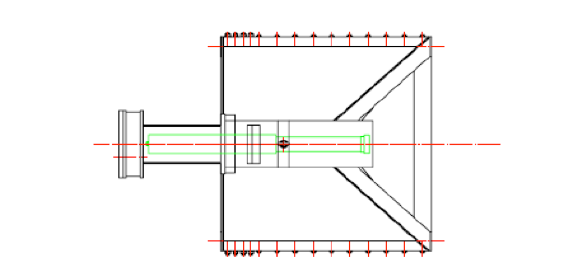

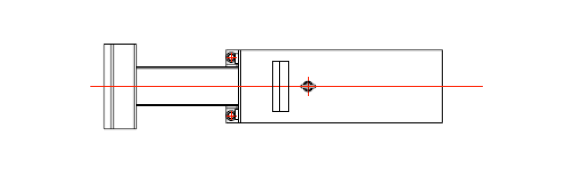

Contains one Oleo Type 76 hydraulic buffer.

Impacting point from the top of rail (coupler height) mm (720 – 660 – 824)

Maximum energy absorbed by buffer: 336kJ

End force: 700kN

Recoverable stroke: 600mm

Examples for conditions and installation length:

(1) 8 Cars

Depot or maintenance workshop. Train mass: 300t, Impacting speed 5km/h, Installation length: 2.7m, Impact capacity: 336kJ, Recoverable stroke: 600mm.

(3) 6 Cars

Depot or maintenance workshop Train mass: 220t, Impacting speed 6km/h, Installation length 2.7m, Impact capacity: 336kJ, Recoverable stroke: 600mm.

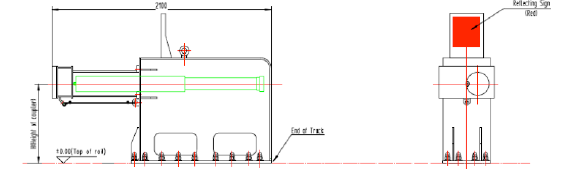

Contains One Oleo Type 76 hydraulic buffer and one set of steel embedded part.

Reinforced concrete base for steel embedded part needed.

Impacting point from the top of rail (coupler height) mm (720 – 660 – 824)

Maximum energy absorbed by buffer: 336kJ

End force: 700kN

Recoverable stroke: 600mm

Examples for conditions and installation length:

(3) 8 Cars

Depot or maintenance workshop – parking area. Train mass: 300t, Impacting speed 5km/h, Installation length: 2.1m, Impact capacity: 336kJ, Recoverable stroke: 600mm.

(4) 6 Cars

Depot or maintenance workshop – parking area. Train mass: 220t, Impacting speed 6km/h, Installation length 2.7m, Impact capacity: 336kJ, Recoverable stroke: 600mm.

Typically used on depot / maintenance workshop - designed for centre impact only. Fixed buffer stop incorporating Oleo hydraulic unit [single Oleo Type 76 - Recoverable stroke 600mm] Installation length: 2.7 metres, Impact capacity 336 kJ.