Leading the world in

energy absorption

Vanguard

MIB International, Moody International

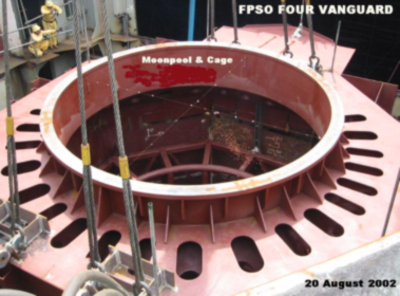

The Four Vanguard FPSO (Floating Production, Storage and Offloading) vessel was refurbished at the Keppel Shipyard in Singapore before being sent back out to Woollybut field in Australia.

An FPSO vessel is designed to receive hydrocarbons produced from nearby platforms or subsea template, process them, and store oil until it can be offloaded onto a tanker or transported through a pipeline. FPSO’s can be a conversion of an oil tanker or can be a vessel built especially for the application.

Moon pools are an opening in the floor or base of a hull, platform or a chamber giving access to the water below. A moon pool was required for the Four Vanguard to allow technicians to lower tools and instrumentation into the sea.

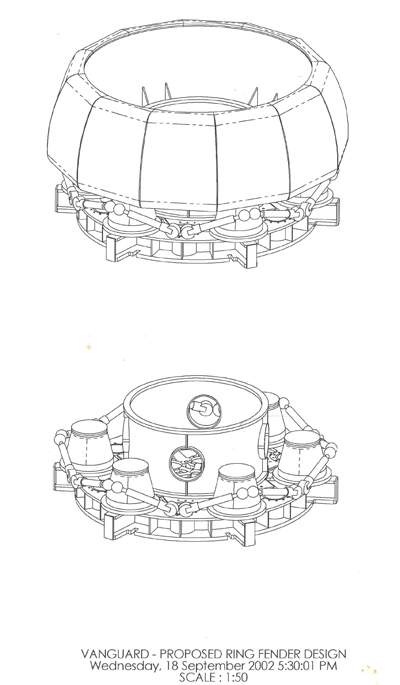

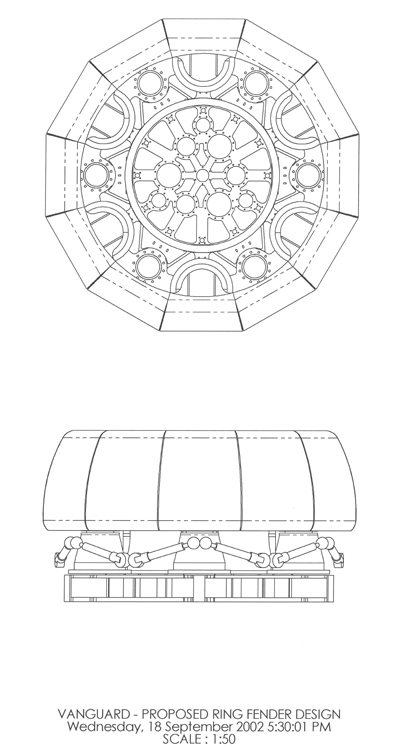

Oleo was commissioned to design a buffer solution for the Four Vanguard moon pool with an underwater fender system with a vertical and lateral movement. The buffers required a single cheek clevis fitted at each end with spherical bearings at the eye of each clevis. The buffers were required to operate at 50m below sea level and therefore needed good corrosion resistance. The buffers were required to have a neutral point (i.e. they needed to be installed at mid stroke). The buffers may be submerged for up to one month so the design needed to accommodate this. Slimy growth was a possibility on the plunger and a minimum design life of 3 years was needed.

Oleo supplied 12 buffers based on Oleo’s Type 9 buffer which offers a maximum force of 700kN a stroke(s) of 400mm and a dynamic capacity of 224kJ. The buffer was installed half stroke allowing a 190mm minimum compression and a maximum 190mm extension.

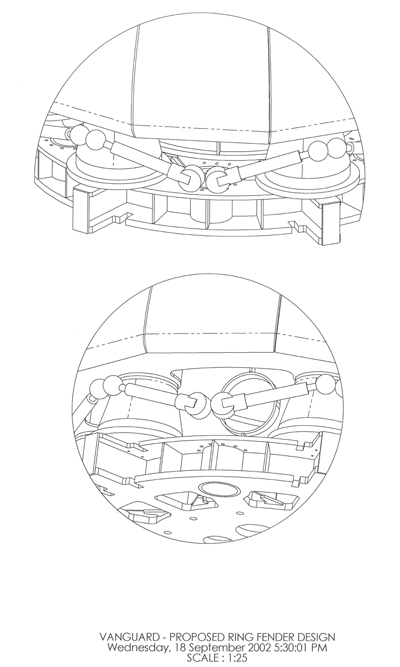

The clevis ends were fitted with o-rings sealing against retaining ring cylinder and plunger to prevent sea water ingress. The clevis ends were produced from carbon steel and painted for protection. All interfaces exposed had superflex-white silicone applied as added protection to prevent the ingress of sea water.

A special wiper blade was fitted into the housing to prevent ingress between the wiper and plunger. The plunger was plated with 90 to 105μm of bronze, then 20 - 30μm of hard chrome.

Cap end screws securing the clevis ends to retaining rings which were made from stainless steel for protection as these were exposed.

A metering pin of 180mm was designed to suit the customer’s performance requirements. The buffer was deflated and shipped in the installed position. Side inflation of nitrogen gas was used due to the design requirements. Once the installation was complete the buffers were inflated on site to the stated pressure. An inflation adaptor was supplied to the client for in situ inflation.