Leading the world in

energy absorption

Stadler (car builder) and Axtone (buffer supplier)

Flirt Train Protection

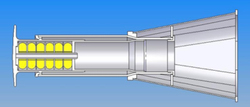

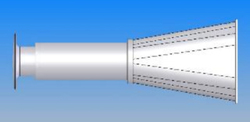

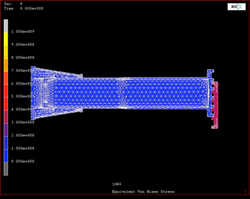

Oleo was commissioned to design and manufacture a hybrid two stage emergency buffer for the Stadler Flirt project which could be mounted directly onto the car structure with minimal rear protection.

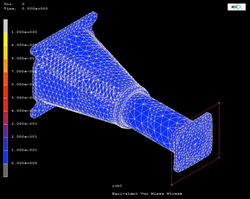

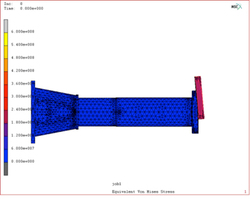

Using our in house simulation software and testing equipment it was possible to develop an emergency buffer which uses deforming element “one-shot” technology both in series and in parallel with the traditional gas hydraulic solutions. This achieved the client’s goal of 382kJ impact energy absorption.

Gas-hydraulic units afford excellent absorption capacity, long stroke units can have a long installed length; conversely, deformation tubes or cellular based technologies are "one-shot" and potentially can require replacement even with a very light impact.

Hybrid gas-hydraulic /deformation tube absorption systems overcome each-others shortcomings resulting in a compact unit which offers a reversible and non-reversible stage giving:

This was achieved for the Flirt as follows:

Reversible:

Elastomer with stroke 110-5mm

Capacity 32kJ

Max buffer force <700kN

Non Reversible:

Deformation total stroke >600mm

Capacity 350kJ

Average buffer force <800kN

Overall Length 1242mm with a buffer head 300mm X 300mm